Student Project

Methodology for Process Customization and Scale-up in LCA within the Food Plastic Packaging Industry: An Eco-design Approach

PhD's Project - [Ongoing]

Student :

Supervisors :

Home » Student Projects » Methodology for Process Customization and Scale-up in LCA within the Food Plastic Packaging Industry: An Eco-design Approach

Plastic packaging is crucial in the food industry for preserving food and reducing waste, but its environmental impact is concerning, especially since most materials are disposed of within the same year they are produced. As the world tries to achieve carbon neutrality, various attempts are being made to develop more sustainable packaging products. Such eco-design relies on the evaluation of the environmental performance of those products at the early stages of their development before their deployment. Life Cycle Assessment (LCA) is a methodology used to assess the environmental performance of products and services over their entire value chain. The challenges in assessing the environmental impact of plastic packaging stem from the variability in technology readiness levels (TRL) of emerging products, with limited data available during early stages of development. Existing life cycle assessment (LCA) models lack the flexibility to accommodate different TRLs, making it difficult to compare packaging materials effectively. Additionally, when modeling novel polymers like bioplastics, factors such as scale, product maturity, and background data add complexity. Finally, integrating LCA into the product design process is crucial, yet challenging, as it requires collaboration with decision-makers to ensure improved environmental performance.

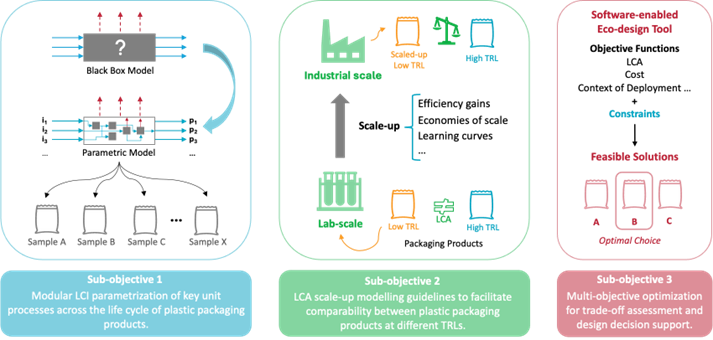

This project aims to tackle those challenges through: (i) parametrizing the life cycle inventory (LCI) of selected unit processes critical to environmental performance and amenable to eco-design interventions during the plastic packaging product design phase, (ii) facilitating the comparability between products of varying TRL by providing clear guidelines for modelling scale up in LCA within the plastic packaging sector, and (iii) incorporating the LCA results with other technical and economic factors into a multi-objective optimization problem to assess the trade-offs between different prospective products and help product design specialists in decision making.

A variable parametrization framework was developed to select and customize unit processes for LCA. For Polyethylene (PE), the steam cracking process was prioritized due to the significant contribution of ethylene production to the overall environmental impact. Key parameters—such as feedstock shares (e.g., NGLs and naphtha), electricity mixes, and thermal efficiency of cracker—can be flexibly varied, while also relying on predefined values that reflect typical regional feedstock availability, grid composition, and cracker performance based on age. Scenario analysis was conducted to (i) compare the environmental impact of the same feedstock processed in different cracker locations, and (ii) assess how different feedstocks perform when processed at the same location. This approach is currently being extended to model the production of bio-based PE, enabling a consistent comparison between fossil- and bio-based routes within the same parametrized framework.